Bearing installation method

1 Use of bearings

Rolling bearings are precision parts. In order to maintain their precision, they must be used carefully and carefully. Keeping the bearings clean, avoiding strong impacts and preventing rust are all things that require special attention when using bearings. 1.1 Storage of bearings

The bearing is coated with anti-rust agent and shipped out after packaging. If the storage environment is appropriate and the packaging is good, it can be stored for several years. The following items should be paid attention to when storing the bearing: (1) Keep it in a place with a relative humidity below 60%. (2) Do not place it directly on the ground, it is better to place it on a stand at least 20 cm from the ground. (3) Pay attention to the height when stacking, and do not stack too much.

1.2 Installation of bearing

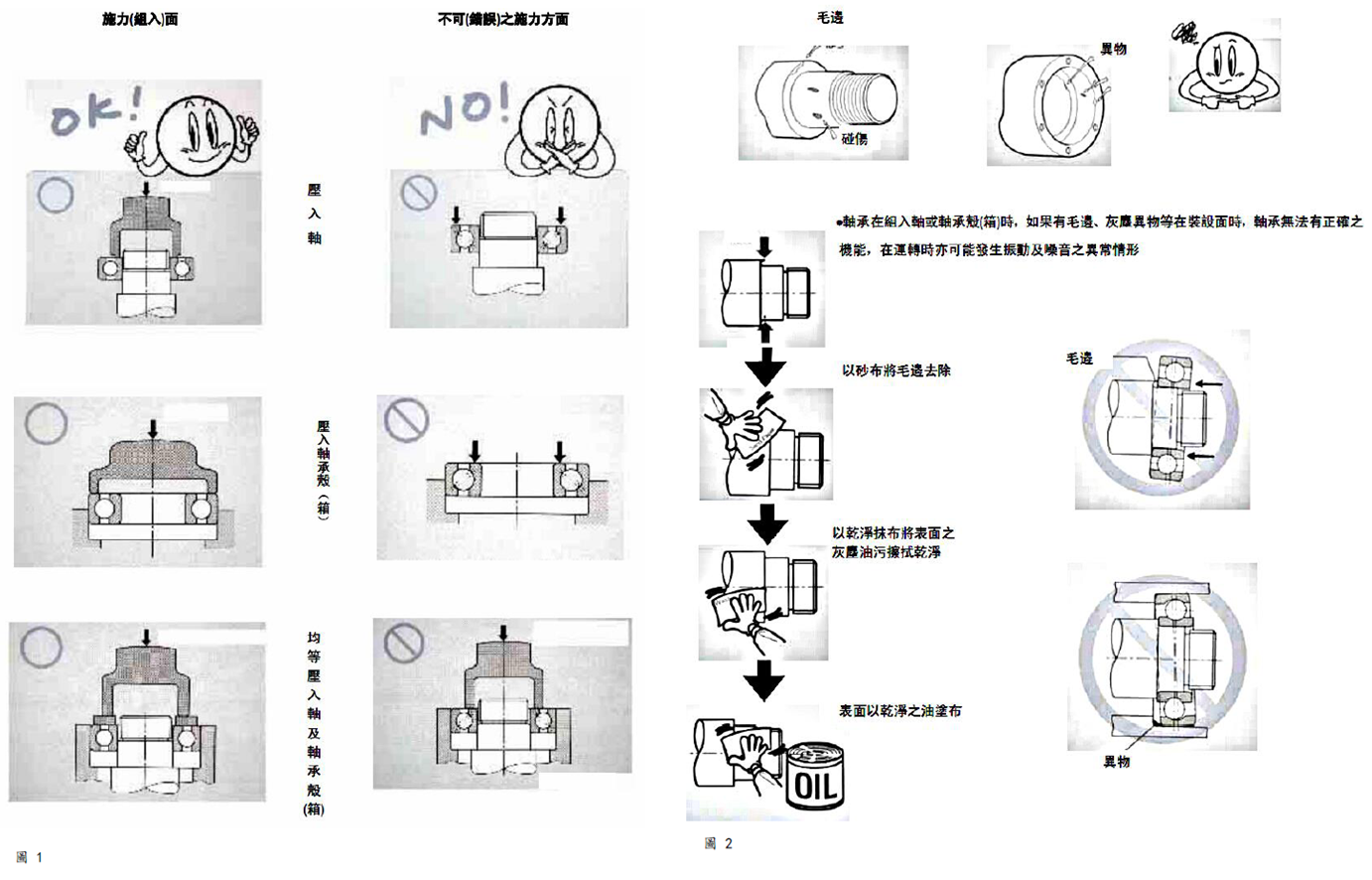

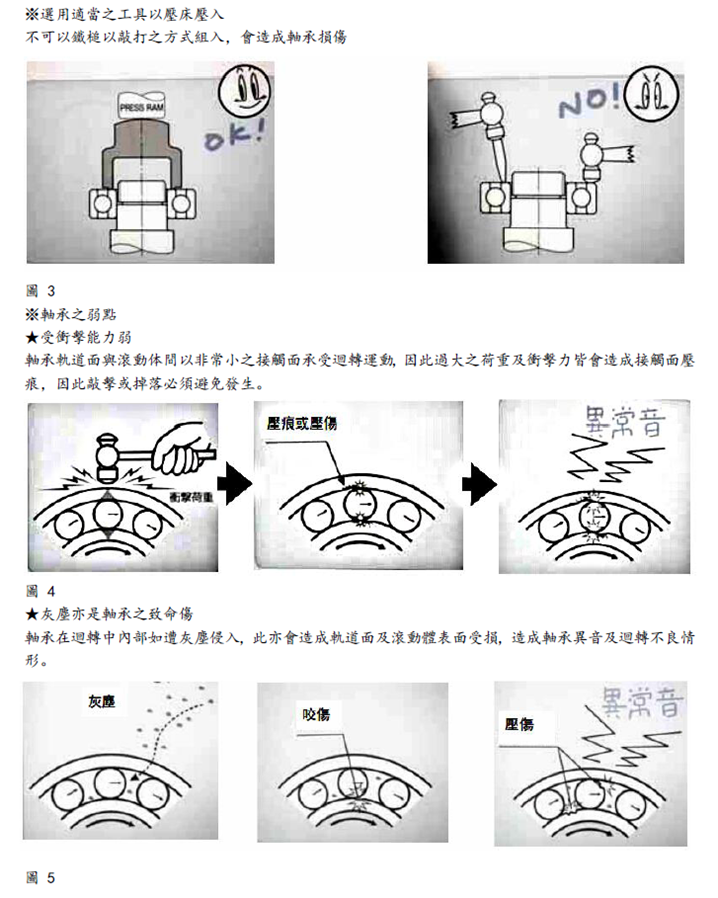

When installing the bearing, directly hitting the end face of the bearing with a hammer may damage the bearing. Therefore, it is necessary to apply equal pressure on the circumference of the track ring to install the track ring. Also, if pressure is applied to one track ring (such as the outer ring) and the other track ring (such as the inner ring) is pressed in through the rolling elements, indentation or scratches will occur on the track surface, which should be avoided.

1.2.1 Preparation before installation

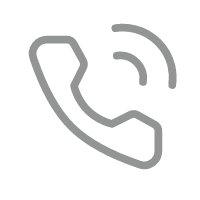

A clean and dry workplace must be provided for bearing installation. In particular, the assembly of ultra-small and ultra-small ball bearings will greatly affect the performance of the bearing if dust invades, so it should be carried out in a clean room, and the dimensional accuracy, shape accuracy and luminosity of the bearing installation part must be checked to confirm that these measurements are in Within the allowable tolerance. (1) Removal of burrs, bumps, protrusions, rust marks, oil stains, etc. on the mating surface of the shaft and bearing shell (box). In addition, a small portion of the end surface should be lubricated with oil, such as spindle oil (spindle oil) when inserted Easier. The operating procedure is shown in Figure 1. (2) Assembling tools, punches or presses, and other assembly tools, select the appropriate size to contact the bearing; the dirt, burrs, chips, etc. on the installation tools must be removed. (3) Bearings Bearings must be unpacked before installation. Also, the bearing is a high-precision product produced in a clean manufacturing process, please do not do any other processing, such as cleaning.

1.2.2 Assembly of bearing

(1) Bearings with smaller tightness The assembly of bearings with smaller tightness can be roughly divided into press-in shafts, press-in bearing boxes, and evenly press-in shafts and bearing shells (boxes), as shown in Figure 2. The assembly method is to use a sleeve to press the end face of the track ring at room temperature, and press the bearing in by the sleeve, and the pressing force acts on the center of the bearing (when the bearing is to be installed on the shaft, force must be applied to the inner ring; the bearing should be installed on the bearing When housing (box), force must be applied to the outer ring), so that the entire circumference of the track ring is evenly pressed in; but if a large number of bearings are installed, the non-separable bearing of the hand press or hydraulic press must be installed in the shaft and the bearing shell at the same time When (box) is installed, press the inner and outer rings evenly into the shaft and bearing shell (box) with a shim. Other matters to be noted, such as not using an iron mallet to be beaten to cause damage and avoid dust intrusion, as shown in Figure 3. (2) When the tightness of the bearing inner ring is large or the shaft diameter is large, if you want to press the inner ring into the shaft at room temperature, you can use the heating mating group that heats the bearing to expand the inner ring before installation. Insertion method (the method of inserting the inner ring by heating and expanding). The required temperature difference between the inner ring and the mating surface is determined by the tightness and the diameter of the mating surface, and the relationship between the temperature difference of the inner diameter of the bearing and the amount of expansion is used. However, standard bearings cannot be heated to 120°C, and they cannot be used for grease-filled bearings and sealed bearings.

1.3 Rotation test

After the bearing is installed, in order to confirm whether the bearing is installed correctly, a rotation test should be done. Rotate manually. If there is no abnormality in the shaft or bearing housing (box), it will rotate with no load and low speed with power, and gradually increase the rotation speed and load while confirming the rotation status. And detect the noise, vibration and temperature rise during the rotation. If an abnormality is found, stop the rotation and check the mechanical device. If necessary, the bearing can be removed for investigation. If you want to detect the rotating sound of the bearing, you can use a listening device to lean on the bearing shell (box) to detect the volume and sound quality. If the sound is clear, it means normal. If there is a sharp metallic sound or an irregular sound, it indicates an abnormality. If a vibration measuring instrument is used to quantitatively measure the amplitude and frequency characteristics of the generated vibration, a more reliable judgment can be obtained. The temperature of the bearing is usually inferred from the temperature of the periphery of the bearing shell (box). However, a more accurate judgment can be made by directly measuring the temperature of the outer ring using oil holes. The bearing temperature rises with the rotation time and reaches a stable and normal state after a certain period of time. If the temperature rises suddenly or shows abnormally high temperature or the temperature does not rise, it means that there is an abnormal state and should be checked.