Bearing production process

Bearing production process

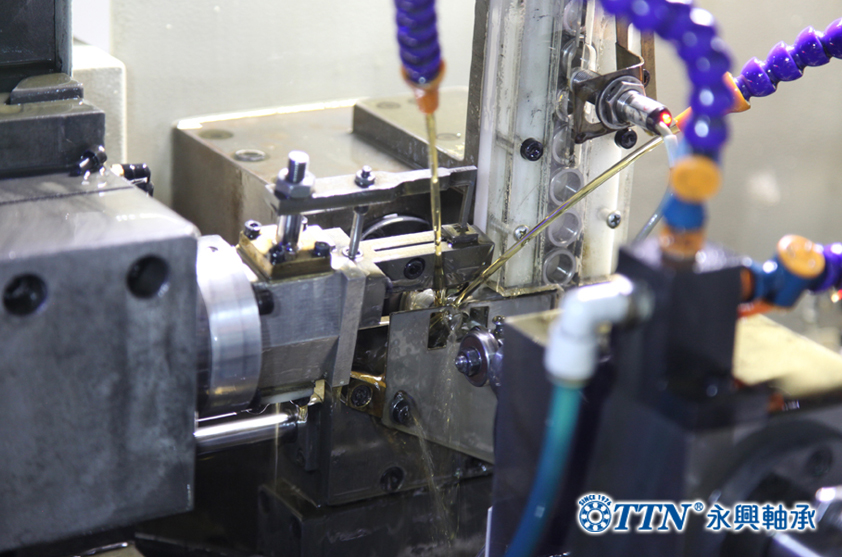

Grind the inner and outer ring end faces

The end face of the ferrule is the positioning datum for the subsequent process. We use the double face grinder to complete the processing of the two end faces of the bearing ring at one time. Compared with the traditional single face grinder M7475 and 4363b, it reduces the error caused by multiple positioning and ensures the high precision requirements of the benchmark processing.

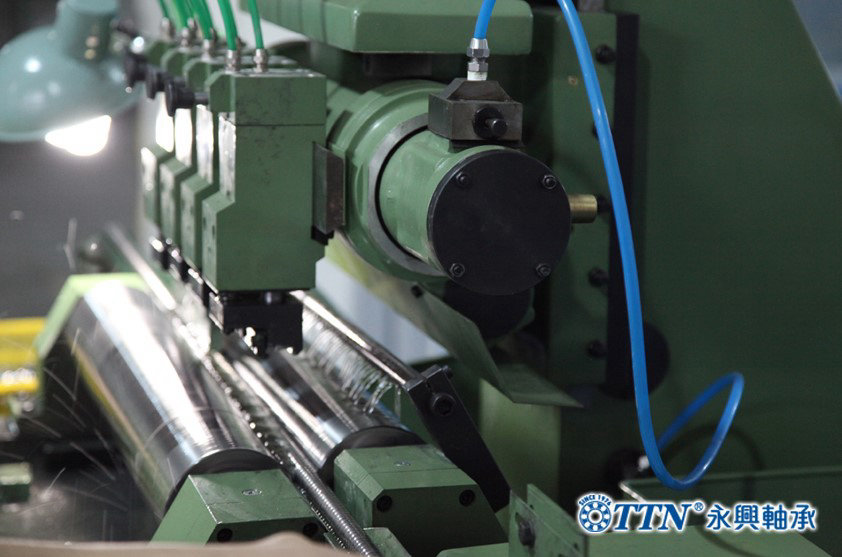

Grinding outer diameter of inner and outer rings

The outer diameter of bearing inner ring and outer ring is also one of the important process benchmarks in the processing of bearing ring. At the same time, the outer diameter of bearing is an important matching surface in the use and installation of bearing. In this process, we use high-precision and wide grinding wheel centerless grinder (processing range 10 ~ 200mm), which is more conducive to ensure the processing stability and processing accuracy (precision can be increased by one time) compared with the traditional ordinary centerless grinder m1050 and m1040 (processing maximum size range 10 ~ 50mm), so as to provide an accurate benchmark for the processing of the next process. The outside diameter of internal grinding is generally 4 times, but in order to improve the benchmark accuracy, our company grinds at least 5 times.

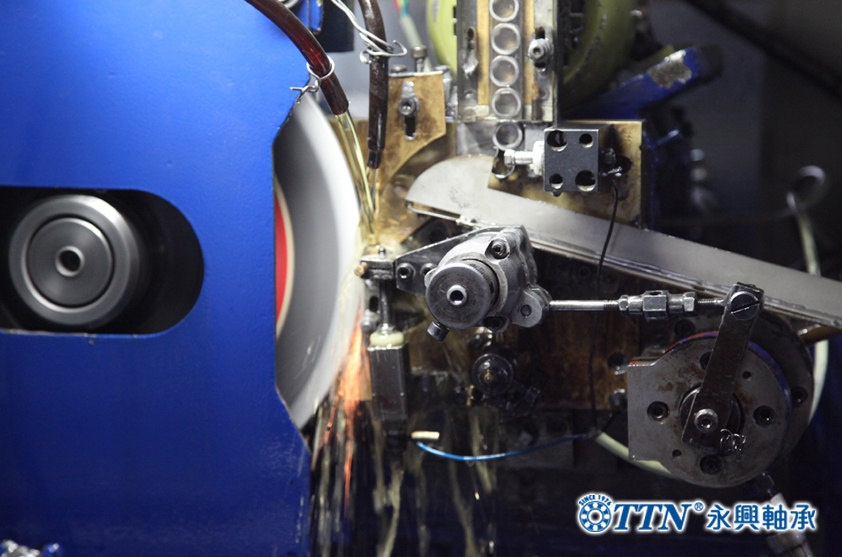

Grinding inner and outer ring channels

The adoption of full-automatic CNC bearing outer ring groove special grinder realizes automatic processing and automatic control, avoids the influence of human operation, so as to ensure the bearing ring groove processing quality, bearing accuracy and service life. In the industry, the grinding feed rate is generally increased to improve the production capacity, and the production capacity of each unit can reach 170000 pieces. However, in order to ensure the product accuracy, our company controls the feed rate, and the production capacity is 100000 pieces / month.

Internal and external channel ultra precision

Our company adopts closed full-automatic special outer ring channel superfinishing machine, which has stable vibration frequency and pressure. General manufacturers in the steel industry use manual superfinishing equipment, and the quality of superfine products is difficult to control. It can effectively improve the surface finish of the channel and ensure the channel quality, so as to reduce the bearing vibration and friction resistance.

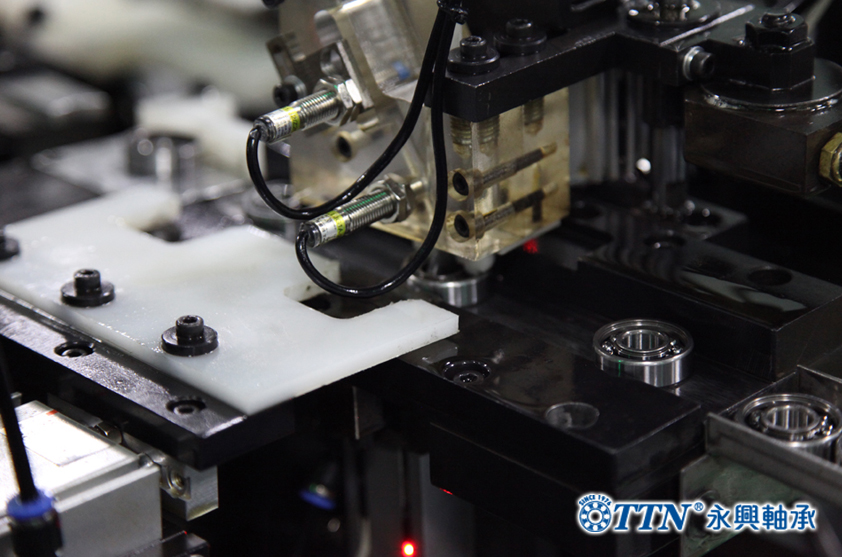

Automatic ball loading sleeve

In order to ensure the accuracy of this parameter value, our products adopt intelligent sorting and nesting instrument to avoid inaccurate and incorrect manual assembly, improve the accuracy of nesting and prevent bumps and scratches. General enterprises in the industry adopt manual or semi-automatic combination.

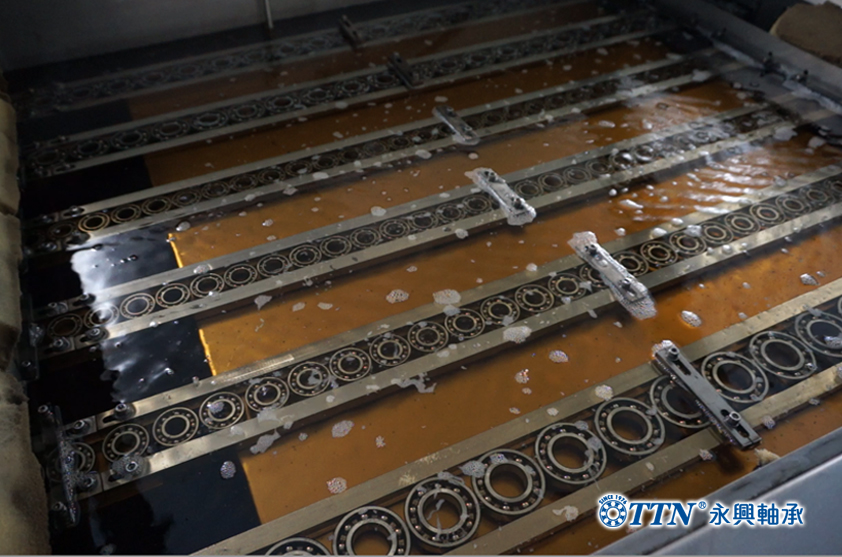

Cleaning of finished and semi-finished products

General enterprises in the industry use single channel batch spraying equipment for cleaning, with a production capacity of 30000 pieces / day. Our six channel single part continuous cleaning line has a capacity of 10000 pieces / day per channel to ensure the cleaning cleanliness of parts.

Grease injection, gland and uniform grease

Automatic grease injection is adopted, unqualified products can be automatically removed, and 100% grease is homogenized to prevent bumping, scratching and rust. Manual grease injection is generally used in the industry, and the grease injection amount is difficult to control.